Evaporator thin film vertical for pharmaceutical chemical use China manufacture Amtech evaporator

- FOB Price

US $20000.001 - 10 piece

US $18000.0011 - 50 piece

- group name

- Evaporator

- Min Order

- 1 piece

- brand name

- Amtech

- model

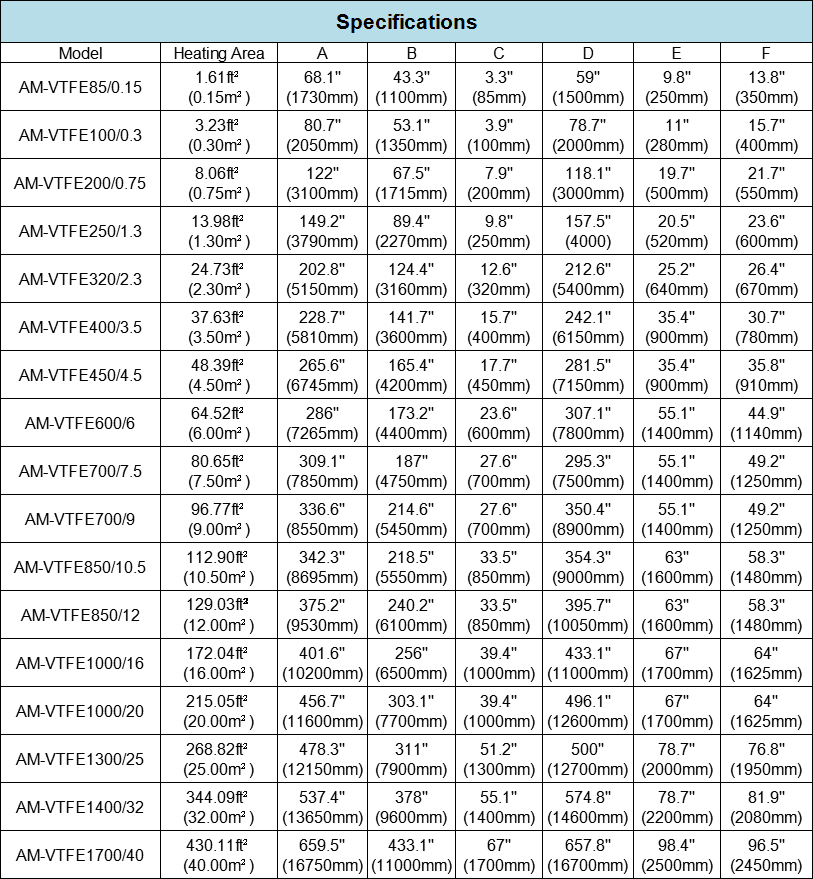

- AM-VTFE

- Nearest port for product export

- Qingdao Port, Shanghai Port

- Delivery clauses under the trade mode

- FOB, EXW

- Acceptable payment methods

- T/T, Westem Union

- update time

- Mon, 06 Jul 2020 15:01:58 GMT

Paramtents

Material Stainless steel 304/316/316L

Usage Pharmaceutical/chemical

Design Customized

Packging & Delivery

- 190cm x 130cm x 172cm

-

Min Order1 piece

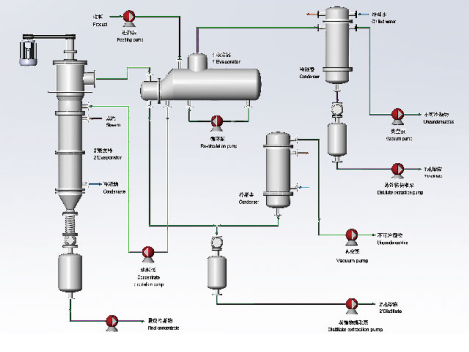

Briefing

Detailed

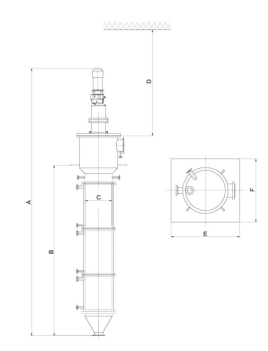

1. Different kinds of rotors available in order to find the most adequate treatment of the product

2. Balanced rotor to minimize vibrations, with final balancing at assembled machine for the best accuracy

3. Double effect mechanical seal with flushing liquid

4. Bottom bush with connection for auxiliary lubrication

5. The lateral discharge version allows the replacement of the bottom bush without removing the conical bottom and the connected piping

6. The machining of the evaporation chamber before the surface finishing ensures the minimum gap with the rotor, the high performance of the thin film evaporator can be thus improved.